Environmental Responsibility

From the moment you open a bottle of our oil, we have already planned its entire journey:

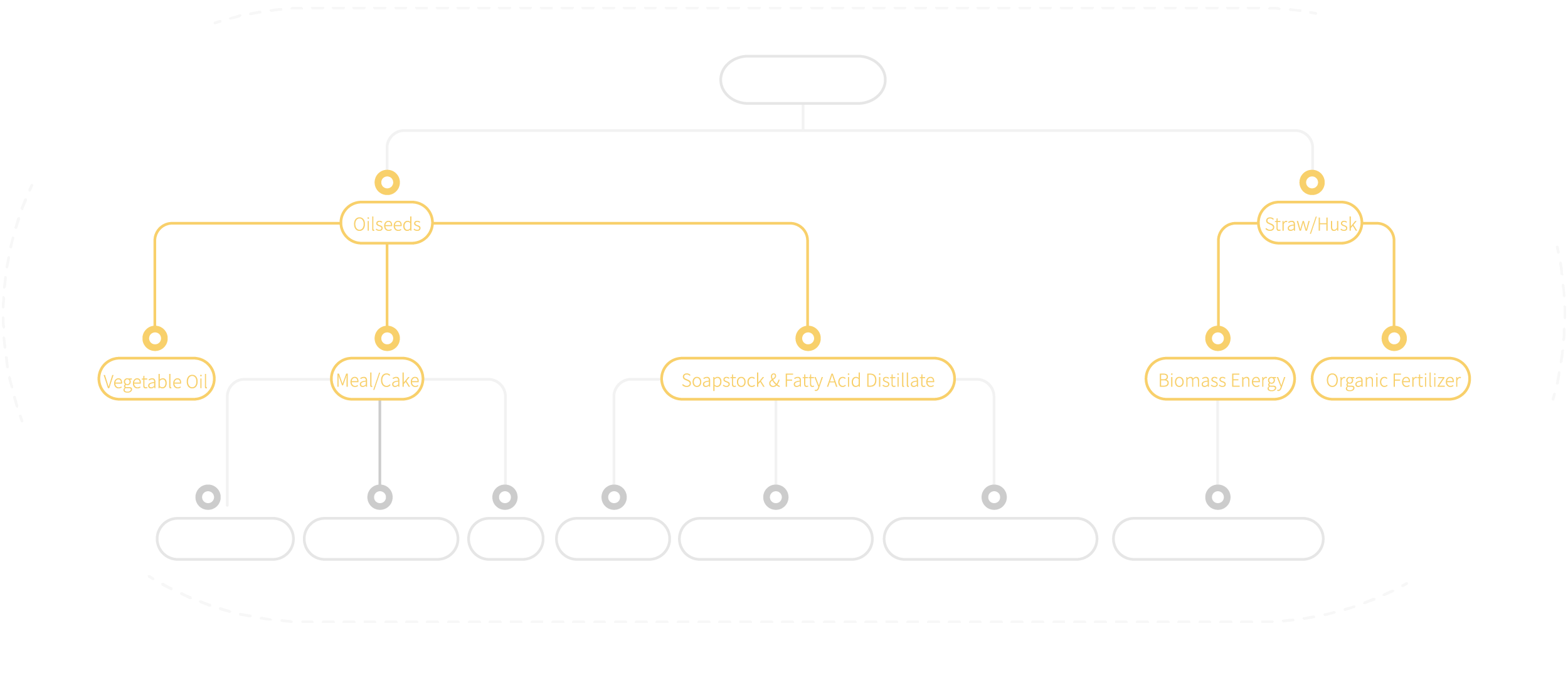

Oilseeds come from sustainable farms with crop rotation and fallow ; straw becomes fertilizer for the adjacent wheat fields;

Used glass bottles are cleaned and reshaped, returning to your life in a new form;

The meal from oil pressing is turned into livestock and poultry feed to nourish cattle and sheep on pastures, which then return to the earth as biofertilizer;

Soapstock from processing is converted into biodiesel, providing green energy for trucks;

Even the last drop of waste oil is converted into energy for agricultural machinery, driving the growth of oilseeds in the next season;

From field to table and back again, each step in the cycle perpetuates renewal.

Green, Precise and Moderate Processing

Mastering key technologies such as precise and moderate oil processing, 3-MCPD ester control, and plasticizer removal to fill the technological gap in high-quality nutritional oils both domestic and abroad. Breaking through technical bottlenecks such as zero trans fatty acids, 3-MCPD, and glycidyl esters, which not only enables precise control of harmful substances but also increases the retention rate of nutrients such as sterols and vitamins to over 90%. By optimizing the production through precise and moderate technology, we reduce energy consumption, inhibit the formation of harmful substances, and retain nutrients from the source to ensure product quality and nutritional value.

Circular Economy

In the exploration of circular economy model, Sanmark actively extends the industrial chain and deeply exploits the potential value of oilseed by-products. The residue from oilseed processing is converted into high-quality protein powder and feed ingredients, which achieves efficient resource utilization and significantly increases product added value. It builds a green circular production system of "leaving no waste behind", It reduces production costs while creating new economic growth opportunities and practicing the concept of sustainability.

Sustainable Production

In sustainable production practice, Sanmark builds a green production system through technology innovation and digital-intelligence transformation. It applies precise and moderate refining technology to reduce the use of chemical additives and energy consumption, replaces old equipment, deploys digital-intelligence production lines to improve production efficiency. Meanwhile, it establishes a comprehensive resource recycling mechanism to efficiently recover afterheat and residual materials, maximizing resource value and providing a model for the green development in the industry.

Sustainable Planting

In the field of sustainable planting, Sanmark lays a solid green foundation from the source and establishes an in-depth cooperation with farmers. By promoting ecological planting technologies, providing green agricultural materials such as organic fertilizers and biological pest control, guiding farmers to adopt scientific planting methods such as crop rotation, fallow, water-saving irrigation, and reducing the use of pesticides, it ensures raw material quality and ecological safety from the source. At the same time, Sanmark provides farmers with technical training and market information, empowering the upgrade of agricultural production, realizing a win-win situation of economic and ecological benefits, and building a green and sustainable chain from field to workshop.

Energy and Water Conservation

In terms of energy and water conservation, Sanmark formulates strict goals and plans, adopting high-efficiency energy-saving equipment and water-saving technologies, and strengthening the measurement, monitoring, and management of energy and water. Sanmark also actively carries out awareness campaigns and training to improve employees' awareness and jointly protect global resources.

Reduction of Pollutant Emissions

Sanmark strictly abides by national and local environmental protection laws and regulations, establishing a comprehensive pollutant control system. Sanmark utilizes advanced pollutant treatment technologies and equipment to ensure that pollutants such as waste water, waste gas, noise, and solid waste comply with standards before discharge. Meanwhile, Sanmark enhances environmental monitoring and data analysis to promptly identify and solve environmental problems.

Social Responsibility

Relieving Hardship, Upholding livelihoods

Sanmark focuses on poverty relief, disaster response, health, and education. In 2023, Sanmark donated flaxseed oil worth RMB 50,000 to the Municipal Charity Federation, and contributed RMB 80,000 over two years in edible oil to support the elderly and people in need. Activities included delivering supplies to nursing homes with commitments to ongoing support. The educational activity of "Edible Oil and Health" was launched alongside nutrition experts to promote health awareness. Since 2006, approximately RMB 200,000 has been allocated annually to support educational programs, including Hope School construction and financial aid for students in need.

Promoting Sustainability, Protecting the Environment

Sanmark establishes a comprehensive environmental management system: installs online monitoring equipment to publicly disclose pollutant data and develop pollution prevention regulations. By-products are converted to biomass fuel, and proprietary technologies reduce emissions. Process innovations enable cooling water reuse and steam condensate recovery. A dedicated EHS department oversees environmental compliance and emergency management systems.

Ensuring Safety, Fortifying Quality

A full-process management based on "Six Core Systems+Nine Support Systems+Four-Level Quality Structure" ensures standardized, intelligent management from source to end product, implementing food safety responsibilities and ensuring product quality through a systematic risk prevention mechanism, providing consumers with trustworthy high-quality products.

Boosting Rural Development, Strengthening Agricultural Foundations

Sanmark innovates with an "Enterprise + Cooperatives + Farmers" model, providing planting guidance and agricultural supplies to farmers in Northeast China, Inner Mongolia, and Gansu. A targeted procurement and price protection mechanism has been established. Currently, the total cultivation area for evening primrose and borage exceeds 23,000 acres, benefiting more than 30,000 rural households. This ensures stable raw material supply and steady farmers' income, achieving mutual benefits.

Enabling Global Partnerships, Driving Worldwide Shared Growth

In 2025, Sanmark officially established its first GMP-certified avocado oil production base in Kenya, injecting momentum into local industrial upgrading through localized operations and green technology transfer.The project creates local jobs and offers agricultural training while building a closed-loop supply chain that ensures raw material quality and income stability. It enhances local industry competitiveness and mitigates poverty, embodying Sanmark’s philosophy: "Sourcing Globally, Serving Globally."

Enabling Global Partnerships, Driving Worldwide Shared Growth

Sanmark prioritizes employees’ sense of happiness and belonging. The company provides a supportive workplace and comprehensive benefits, promoting physical and mental wellness. Regular training and career development programs help enhance skills and professional growth. A dedicated employee care mechanism addresses both personal and professional needs, fostering a harmonious corporate culture.

Corporate Governance

Business Ethics

In all business practices, Sanmark operates with integrity and fair competition. Sanmark respects the interests of clients, suppliers, and partners, consistently honoring contracts and commitments to maintain a strong reputation. Additionally, Sanmark actively fulfils its social responsibilities and promotes industry self-regulation and the development of a credibility-based social system.

Compliance Management

Sanmark strictly adheres to national laws, regulations, and industry standards, supported by a comprehensive compliance management system. Regular compliance training enhances employees’ awareness and risk prevention capabilities. Internal audits and supervisory mechanisms are reinforced to ensure all business activities remain compliant and lawful.